Tova, the loyal shop dog and reliable trigger-happy alarm system, came to us as a rescue from Northern Minnesota. Accompanying her unknown sojourns of the great North came welcome habits and one or two unwelcome instincts. If prey is afoot, she is of a single mind; the most tempting treats struggle to break her pointed focus. Given the constraints of city living and a non-fenced front yard, it seems her ideal day might include watching through the front windows over our small slice of Minneapolis. But alas, our typical window sills are just above her resting eye level when standing and no furniture is oriented for optimal rabbit reconnaissance. This project may be just the watchtower she needs.

We’ve fallen into a healthy daily habit with Tova including a run each morning and a long walk at the end of the workday. To avoid the spring mud near the gardens, we enter and exit the house through the ally and often treat ourselves to a walking tour of the block’s trash and recycling bins. Within one exquisite exhibit of solid waste offcuts, discarded cabinets, and misfit table legs (it looks our neighbor was moving in a hurry), lay buried several pre-finished door panels measuring 15″ x 18″, 7 panels in all. Bazinga!

I find it satisfying to find and repurpose material discarded by others and that may otherwise be wasted. Why buy new when so much is still waiting for a purpose?

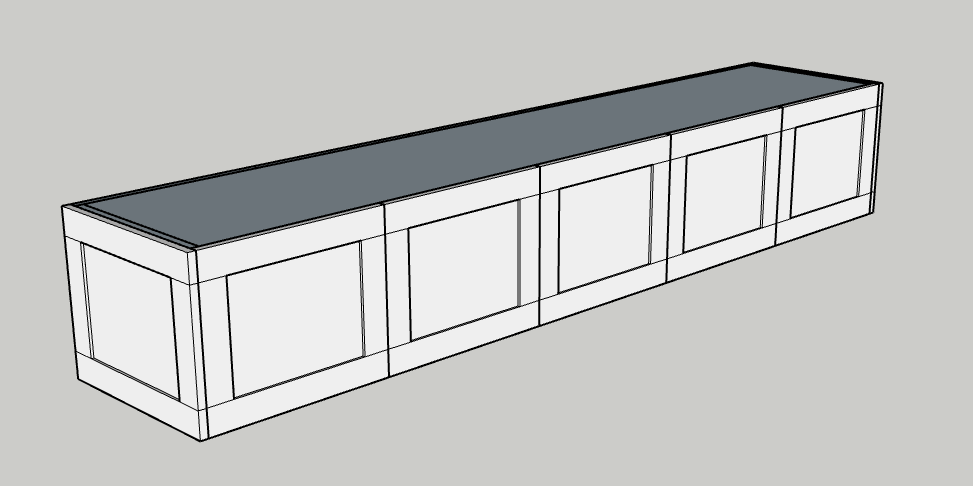

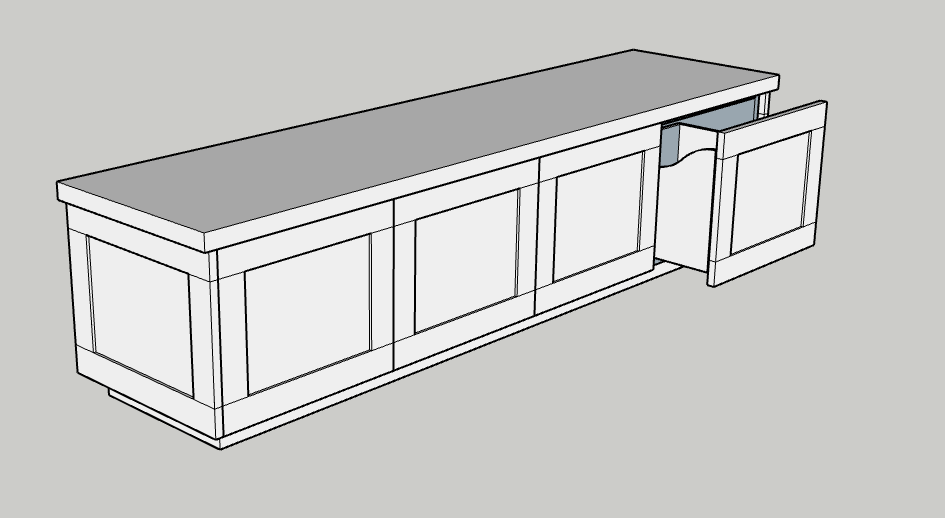

The front entry to our house lacks a perch for Tova’s daytime duties and also a seat to park ourselves while we slip on shoes. Given the materials at hand, the my next project is a long window bench with built-in shoe storage in full-extension drawers.

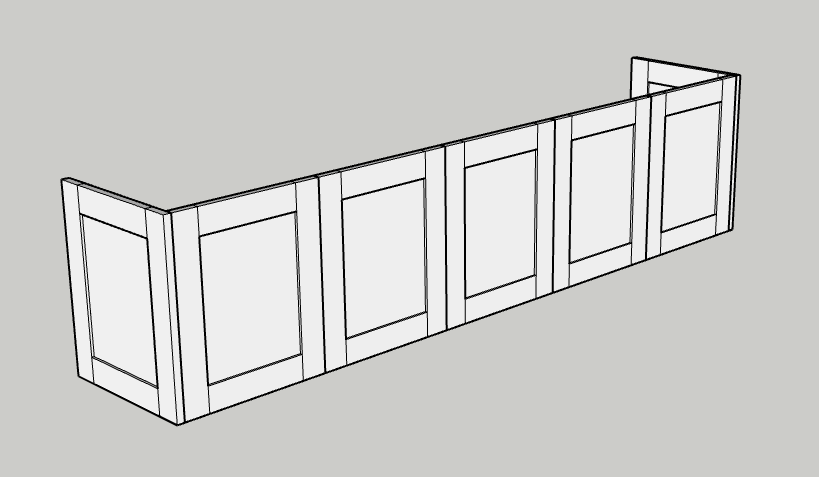

The bench design is formulated on a base-unit: the prefinished door panel. The length is an increment of one of the side dimensions. Proportions of the overall bench are dependent on the orientation of the panels and the number of panels used in the project. With 7 panels I have a variety of permutations. I want to use one panel for each side to provide an appealing finished end surface, leaving 5 panels to use along the face of the bench.

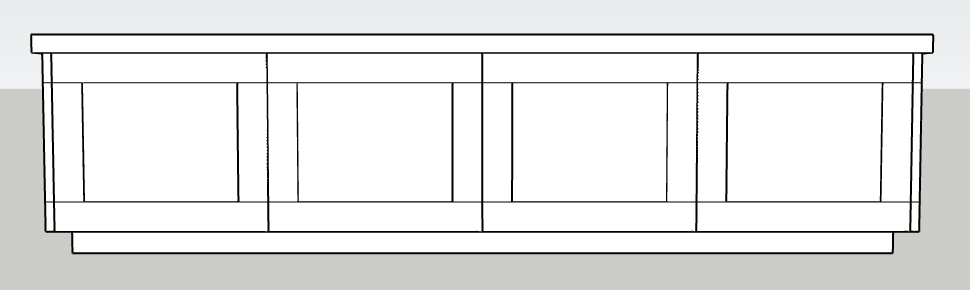

Oriented ‘vertically’ the bench is at least 18″ tall and 15″ deep. With all five remaining panels used across the front, the length is about 75″ plus an inch or two for gaps and end sections. The resulting proportions appear arcane and akin to a medieval jointed chest. Not that this a bad look, just not an aesthetic that fits our other furniture.

If I rotate all of the panels 90 degrees such that the bench is 15″ tall and 18″ deep, the resulting form is something closer to mid-century modern. The overall length is greatly increased to over 90″. However, the low seat height and exaggerated length are both too short and too long to be functional in the intended space.

While preserving the panel orientation and aesthetic, removing a panel and adding a pedestal results in a robust and functional form from which we can further refine the design. Fear not for the lonely panel omitted from the bench; I plan to use the panel as the door in a small wall cabinet that will feature in an upcoming post.

Keeping true to my penchant for material reuse, I recently salvaged several large pine panels that had previously been used as a shipping crate. The panels are all S4S and contain fewer knots that I would expect for utility-grade pine boards – the crate must have contained some major award! In any case, these boards are now onto at least their third life as the main structural case of this bench. As much of the bench will be covered by the prefinished panels, the appearance of the casework is far less important. Despite their unsightly grain and occasional shipping stamp, the panels and case joinery will provide ample strength and durability for the main bench structure.

At the corners of the case, I plan to use thru-dovetails that will be concealed by the top assembly and end panels. Rather than place the tails on the vertical side pieces, I’ll instead place them on the top and bottom boards. Since we don’t want a floating bench, the sides will experience mainly compression forces for the majority of the life of the bench, apart from handling during moves. Gravity will help to hold the pins into the top and bottom, but when the bench is subjected to racking (sideways pushes from the squirrel sentry) the corner joints will be folded together or pried apart. Mind you, there will be little visible movement, but the joint may weaken over repetitive cycles of this loading. Think of an old dining table chair, the joints were likely tight and stiff when made anew, but joint rotation from the inevitable scooting and sliding weakened the joints that now creek and moan under the slightest bum readjustment. The same will occur in a bench, albeit over a much greater joint area. With the pins oriented vertically from sides, the side boards are effectively held ‘into’ the bench case. When the bench racks, the horizontal tails provide a mechanical lock preventing the sides from tipping out and away from the case. This is actually the same mechanical interaction that would be occurring if the pins and tails were switched, but as I mentioned earlier, we can optimize the joint resistance with the gravity-positive, pin-vertical orientation.

That’s enough design talk and reuse ramble for now. I’ll be back with more discussion on the back panel, top, and drawer assemblies in Part II.